Software Introduction

Software Introduction

Overall System Architecture

New Energy Industry System Architecture (Single Line / Multi-Line)

FMS Functional Architecture

Monitor and manage on-site equipment, and conduct scheduling management for logistics equipment.

Schedule and manage the battery cell production process based on its manufacturing procedures.

Manage process recipes and parameters for charge and discharge cabinets.

Monitor equipment and storage locations in real time.

Display multi-dimensional data analysis functions based on battery cell production data and equipment data.

FMS Process Configuration Management

Multi-process production plan configuration

Bind production plans based on pallet type

Bind production plans based on battery cell batch/type

Customizable process logic configuration

Modular scheduling nodes, supporting secondary development

Drag-and-drop visual editing of process workflows

Multi-process production allowing mixed-line production based on batch and model

Administrators can adjust pallet production status in real-time through the system

FMS Flexible Empty Pallet Scheduling Management

Empty pallet registration

Palletizing equipment management

Automated empty pallet delivery

Automated empty pallet racking for buffering and replenishment

Configurable empty pallet scheduling parameters to adapt to different on-site needs

Real-time inventory visualization for empty pallets to detect anomalies promptly

Manual empty pallet call function to support offline operations

FMS Fixture Scheduling Management

Fixture registration

Fixture plan configuration

Automated fixture retrieval and buffering

Trigger-based fixture operations

Scheduled fixture operations

Visual editing of fixture scheduling strategies

Adaptation to various industrial types and processes

Ability to arrange alternative fixture operations based on inspection results

FMS Power Production Recipe Management

Power cabinet process recipe parameter settings

Power cabinet process recipe issuance

Power cabinet process recipe query

DCIR recipe management

OCV recipe management

Centralized management of power cabinet recipes, allowing recipe issuance based on battery cell model and batch, reducing the workload of on-site management personnel.

FMS Power Cabinet Monitoring

Power Cabinet Process Recipe Parameter Settings

Power Cabinet Process Recipe Issuance

Power Cabinet Process Recipe Query

DCIR Recipe Management

OCV Recipe Management

Centralized management of power cabinet recipes allows recipe issuance based on battery cell model and batch, reducing the workload of on-site management personnel.

FMS Charge & Discharge Curve

WMS Functional Architecture

WMS Strategies & Operation Processes

WMS Inventory Management

WMS Multi-Level Distribution & Line-Side Warehouse Management

WMS Dynamic Interface Diagram

Stocked Status

Reserved Status

Empty Pallet Shelving Status

Actual Pallet Process Status

Storage Location Abnormal Status

Overtime Pallet Status

Manual Lock – Locked by scheduling

Business Lock – Locked by ECS

Dual Lock – Locked by both scheduling and ECS

WMS System Features

Granular Permission Management

Visual Interface

Mobile Terminal

Barcode (RFID) Management

Terminal Display

Report & Log Management

Interface Integration

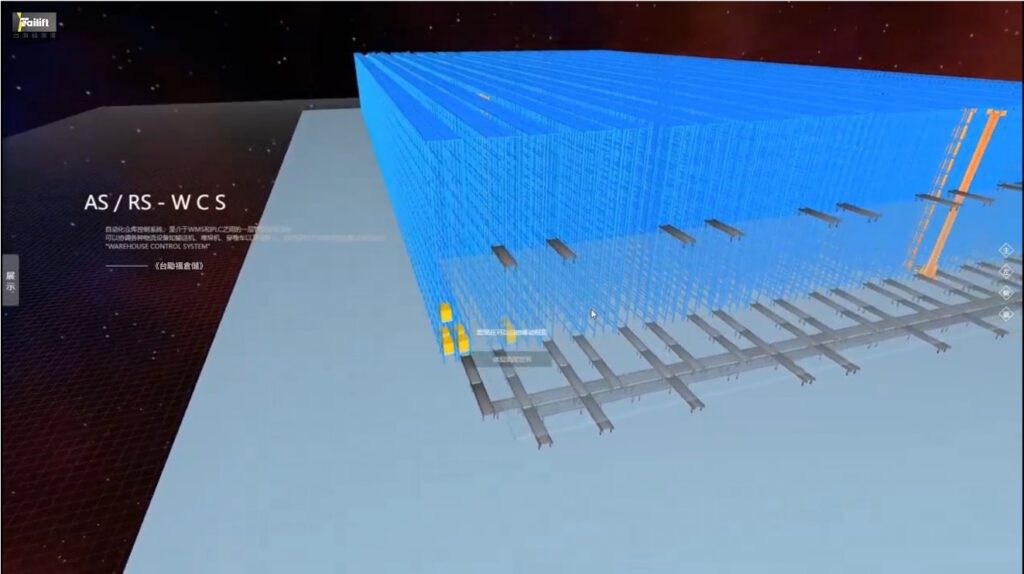

WCS Functional Architecture

WCS System Introduction - Scheduling Module

- Custom Monitoring Zones

- Drag-and-drop configuration to accelerate production line integration.

- Real-time equipment status monitoring for timely production line insights

- Optimal Route Selection & Flexible Logistics Scheduling:Dynamically adjust transportation routes based on conveyor line layout, real-time congestion, and equipment status to ensure material accessibility.

Automatic Pathfinding & Route Navigation:

If there is a deviation in the execution of a transportation task, or if a pallet is manually moved in or out of the logistics line, the system can automatically correct the transportation route and guide the material back to the correct path, ensuring accurate material delivery.

WCS Equipment Execution Scheduling

Generate pallet process tasks based on process plans and create logistics instructions through scheduling.

For example, if valid paths from A to D include A → B → C → D and A → B → D, when the pallet reaches point B, the system evaluates the real-time accessibility of B → C and B → D. Based on route optimization strategies, the best path is selected.

Utilizes advanced automatic pathfinding algorithms and a dynamic logistics scheduling model.

The platform automatically calculates the optimal route, ensuring faster and more accurate material flow between production and warehouses while preventing congestion.

Proprietary drag-and-drop routing configuration simplifies logistics route management, making it accessible beyond software engineers.

Software System Architecture Diagram

Real-Time Monitoring Room

Functions:

Fast and Convenient Monitoring of the overall system operation status

Real-time Display of detailed operating statuses for various equipment

Voice Alerts for equipment failures

Advantages:

- Convenient On-Site Maintenance & Management – System maintenance personnel can monitor the overall system status directly from the control room.

- Quick & Timely Fault Localization – Rapidly identifies the source of issues.

- Enhanced Safety – Improves safety in on-site maintenance and management.

- Customizable, Independently Developed Monitoring System – Flexible to meet specific needs.

- Voice Alerts – Reduces the workload of on-site managers.

Table of Contents

- Overall System Architecture

- New Energy Industry System Architecture

- FMS Functional Architecture

- FMS Process Configuration Management

- FMS Flexible Empty Pallet Scheduling Management

- FMS Fixture Scheduling Management

- FMS Power Production Recipe Management

- FMS Power Cabinet Monitoring

- FMS Charge & Discharge Curve

- WMS Functional Architecture

- WMS Strategies & Operation Processes

- WMS Inventory Management

- WMS Multi-Level Distribution & Line-Side Warehouse Management

- WMS Dynamic Interface Diagram

- WMS System Features

- WCS Functional Architecture

- WCS System Introduction - Scheduling Module

- WCS Equipment Execution Scheduling

- Software System Architecture Diagram

- Real-Time Monitoring Room

Case Display

Case

© 2026 Copyright Tailift Co., Ltd. All Rights Reserved. | Designed by